petit rock crusher jaw

Jaw crusher EB FLSmidth

This rock jaw crusher makes crushing hard rock and ore look easy. Unmatched robustness and longevity Incorporating the latest technology, the Jaw Crusher EB series consisting

Consulter un spécialiste

Jaw Crusher - Eastman Rock Crusher

10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle

Consulter un spécialiste

McLanahan Jaw Crushers

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and sometimes

Consulter un spécialiste

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

产品. 粉碎设备. 颚式粉碎仪. Retsch颚式破碎机用于中硬性、硬性、脆性、韧性材料的快速、强力破碎和预破碎。 所提供研磨材质的多样性、效率和安全性使颚式破碎机成为实验室

Consulter un spécialiste

Mobile Jaw Crusher Portable Mini Stone Rock Crusher Machine

2024年1月13日 Basic Info. Model NO. GTCO. Inlet Size. 900×1200mm. Condition. New. Warranty. China. After-sales Service. China. Types. PE Jaw Crusher. Conditions. New.

Consulter un spécialiste

1-5tph Mini Diesel Mobile Rock Crushing Machine/Small Portable Stone ...

2024年1月8日 1-5tph Mini Diesel Mobile Rock Crushing Machine/Small Portable Stone Jaw Crusher Price PE 150X250 for Sale. Reference FOB Price. Get Latest Price. US

Consulter un spécialiste

Jaw Crushers Retsch - @dkshgroup

3 天之前 Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials offered, their

Consulter un spécialiste

Jaw Crushers - Parker Plant

1 天前 Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units have been installed around the world. ...

Consulter un spécialiste

Jaw Crusher,Small Jaw Crusher,PE Jaw

2022年4月24日 Send Enquiry. Description of Jaw Crusher. Jaw crusher can be used together with gravel processing equipment as well as used independently. Hongxing small jaw crusher, PE jaw crusher and mini jaw

Consulter un spécialiste

Jaw crusher EB FLSmidth

This rock jaw crusher makes crushing hard rock and ore look easy. Unmatched robustness and longevity. Incorporating the latest technology, the Jaw Crusher EB series consisting of a standard model range and Pro series delivers high performance thanks to the optimised geometry of the crushing chamber. With a good intake angle and aggressive ...

Consulter un spécialiste

Types of Crushers: What You Need to Know - Machinery

Eli Whitney Blake invented, patented, and sold the first actual rock crusher in 1858, it was known as the Blake Jaw Crusher. Blake’s crusher was so influential that today’s models are still compared to his original designs. This is because the Blake Jaw Crusher integrated a key mechanical principle – the toggle linkage – a concept ...

Consulter un spécialiste

Rock Crusher - Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing

Consulter un spécialiste

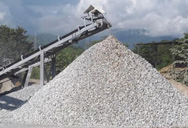

Processing of Construction and Demolition Waste

2022年3月24日 The first jaw crusher was developed by Blake in 1858 for rock and ore processing. Depending on the type of power transmission, a distinction is made between double-toggle jaw crushers and single-toggle jaw crushers. The single-toggle jaw crusher is preferred for use in construction and demolition waste processing plants.

Consulter un spécialiste

Jaw Crushers - Armstrong Equipment

JC3660 Jaw Crusher: 107,664 (48,836) 36 x 60 (915 x 1524) 250-300 (186-224) JC5460 Jaw Crusher: 196,258 (89,021) ... Typical applications for our single-toggle jaw crushers are in mining, quarrying and recycling. The jaw crushers handle ores, rock, gravel and recycled concrete. Specs; Features; Options; Downloads; Product Weight in lbs (kg ...

Consulter un spécialiste

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

Consulter un spécialiste

Modeling of the Interaction between a Rock Being Processed

2021年3月10日 Abstract In this article, a model of the interaction between the jaw of a vibratory jaw crusher with the rock under processing in the form of a lump material is considered. To describe the motion of the rock and its sequential fracture into finer fragments, the crushing chamber is divided into zones of equal height. In each current

Consulter un spécialiste

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Consulter un spécialiste

Mobile crushers and screens - SRP

In order to bring the most powerful rock crushers, scalpers and screeners to the most difficult of jobs, we have pioneered revolutionary machines with the highest levels of agility and mobility. ... CJ412 jaw crusher . Feed opening 1200 x 830 mm (47 x 33 in.) Max. feed size 750 mm (30 in.) Capacity 700 mtph (770 stph) UJ440i Jaw crusher ...

Consulter un spécialiste

What Is A Jaw Crusher - MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)

Consulter un spécialiste

What is the best type of crusher for hard rock? - LinkedIn

2023年3月7日 The best type of crusher for hard rock is a jaw crusher. Jaw crushers can handle very large pieces of rock, and are able to produce a finely crushed product with a relatively small motor. They are ...

Consulter un spécialiste

Modeling of the Interaction between a Rock Being Processed

2021年3月10日 Abstract In this article, a model of the interaction between the jaw of a vibratory jaw crusher with the rock under processing in the form of a lump material is considered. To describe the motion of the rock and its sequential fracture into finer fragments, the crushing chamber is divided into zones of equal height. In each current

Consulter un spécialiste

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Consulter un spécialiste

Mobile crushers and screens - SRP

In order to bring the most powerful rock crushers, scalpers and screeners to the most difficult of jobs, we have pioneered revolutionary machines with the highest levels of agility and mobility. ... CJ412 jaw crusher . Feed opening 1200 x 830 mm (47 x 33 in.) Max. feed size 750 mm (30 in.) Capacity 700 mtph (770 stph) UJ440i Jaw crusher ...

Consulter un spécialiste

What Is A Jaw Crusher - MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)

Consulter un spécialiste

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

6 天之前 A jaw crusher is an important piece of machinery that helps break aggregate material down into the right size. Learn more about this machine on our blog today. ... the bottom of the “V”-aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it is small ...

Consulter un spécialiste

fr/rock crusher portable petit.md at main liyingliang2022/fr

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Consulter un spécialiste

Performance optimization of jaw-type rock crushing

2019年12月11日 The results show that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jaw-type crusher shaft. The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 13.1×10 5 kN/m 2 and capable of crushing 425–569 kg of ...

Consulter un spécialiste

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Jaw rock crusher VS gyratory crusher Different crushing principles Jaw crusher is a compression type of crushing machine. The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a compressive force squeezes raw

Consulter un spécialiste

Rock Crushers For Sale - Multiple Types For Your Needs

It has a large crushing capacity, and high efficiency, and is not easy to grind. A jaw rock crusher for sale is a kind of crusher with the longest development time, so its function is more strong, which also further expands the application scope of the jaw rock crusher. APJ-5075E jaw rock crusher Capacity: 40-110(t/h) Model: APJ-5075E;

Consulter un spécialiste

Article aléatoire

- la machine concasseur de craie a Hyderabad

- de concasseur Concasseur à cone

- Machine de poudre de Feldspath

- pièces de rechange de l'usine fournisseur

- mine de charbon hautes alpes

- angle maximal de pincement sur concasseur giratoire

- mini concasseur de pierre concasseur à machines

- broyeur de mâchoire bentonite a vendre

- Sayaji ligne concasseur cle en main inde

- concassage brevets de machines

- concasseur de minerai Chine concasseur

- résidus or processus de récupération

- terres rareséquipements de traitement des minéraux

- inventorisation de broyeur de pierres dans différents états

- Procédé de criblage de minerai de fer

- équipements de minerai de fer d enrichissement Irlande

- machine de broyage de Charbon humide

- broyeur pour peinture de chavet

- prix meuleuse humides à Vijayawada

- Région de la baie de broyage du béton

- usines de broyage de laitier en turquie

- à vendre forage de minerai de fer

- classificateurs de cendres fabricant voler

- fabricants de machines aluminium de fer plaques

- chaine de production de Graphite

- pcuivretable pierre concasseur à machines

- techniques de broyeurs à boulets à cha ne

- concassage et de transport

- coût de broyeur de conception

- transport du charbon en Indonésie